Digital Thinkers

Responsibilities

- Development

- Webapp

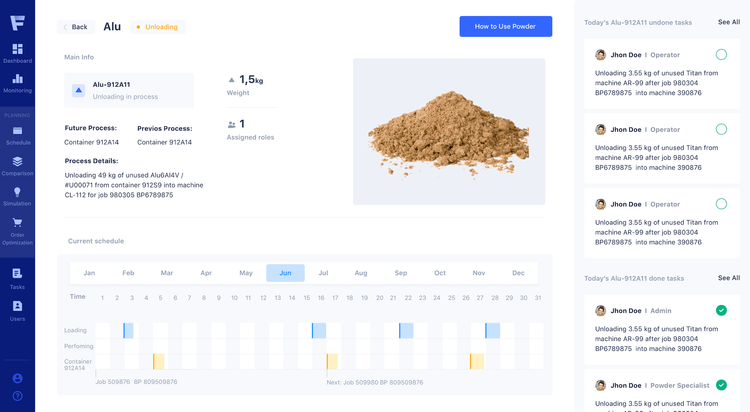

In most factories, it is a huge challenge to handle unexpected orders, redesign the manufacturing process due to potentially failing machines, and resolve temporary human defects or raw material problems. GP Sys addresses this extremely complex set of problems by incorporating more than 200 different parameters to increase manufacturing efficiency and achieve different business goals.

Problem

Translating the mathematical and genetic algorithms behind the complex system into a developer language and then creating a stable system was a major challenge that required continuous customer communication and a highly trained team.

Solution

We have designed a system that can handle, monitor, calculate and process hundreds of inbound parameters and then deliver them in a way that users can understand.

As our team creates additional software capabilities, the system is already being implemented in various organizations as a consequence of our efforts.